Shockproof Safety: The Ultimate Guide to Choosing High Voltage Lineman Gloves

Fri, 23 May 2025

When it comes to working with high voltage systems, safety should always be your top priority. Lineman gloves are more than just a piece of gear; they are your first line of defense against electrical hazards. But with countless options available, how do you choose the right pair? In this ultimate guide to high voltage lineman gloves, we’ll explore everything you need to know to make an informed decision.

From understanding the materials and insulation ratings to assessing comfort and dexterity, we’ll break down the essential features that ensure both protection and performance. Whether you’re a seasoned professional or just starting in the field, equipping yourself with shockproof safety gear is non-negotiable. Get ready to delve into the world of lineman gloves and empower yourself with the knowledge to select the best gloves for your safety and success.

ASTM D120 Specification for Rubber Insulating Gloves

Shockproof Safety: The Ultimate Guide to Choosing High Voltage Lineman Gloves

Understanding High Voltage Lineman Gloves

High voltage lineman gloves are a specialized type of personal protective equipment (PPE) designed specifically for electrical workers who handle high voltage systems. These gloves are engineered to provide a critical barrier between the worker and the potentially deadly electrical currents they encounter on the job. The importance of these gloves cannot be overstated, as they are often the first and most crucial line of defense in preventing electrical shock injuries and fatalities.

OSHA’s guidelines on personal protective equipment

The construction of high voltage lineman gloves typically involves layers of insulating materials such as rubber, which are capable of withstanding high levels of electrical voltage. These materials are carefully tested to ensure their effectiveness in blocking electrical currents. Additionally, the gloves often feature ergonomic designs to ensure that they do not inhibit the dexterity and comfort necessary for performing intricate tasks. This combination of protection and usability is what makes lineman gloves indispensable in high-risk environments.

Understanding the specific needs of high voltage linemen is key to appreciating why these gloves are so essential. Electrical workers are often required to perform their duties in challenging conditions, such as at great heights, in confined spaces, or under adverse weather conditions. In these situations, the reliability of their gloves can mean the difference between life and death. Therefore, choosing the right pair of high voltage lineman gloves is not just a matter of preference; it is a critical safety decision that requires careful consideration of various factors.

Importance of Shockproof Safety in Electrical Work

In the world of electrical work, shockproof safety is paramount. Electrical hazards are among the most dangerous risks faced by workers, capable of causing severe injuries or even death within a fraction of a second. The primary function of shockproof lineman gloves is to insulate and protect the worker from these hazards. This involves not only preventing direct electrical contact but also ensuring that the gloves can withstand the high voltage levels commonly encountered in the field.

One of the foremost reasons for emphasizing shockproof safety is the nature of electrical accidents. Unlike other workplace injuries, electrical shocks can result in immediate and catastrophic consequences. High voltage electrical currents can cause burns, cardiac arrest, nerve damage, and other serious health issues. Moreover, the effects of an electrical shock can be long-lasting, impacting an individual’s ability to work and quality of life. This makes the role of high-quality, reliable lineman gloves absolutely critical.

The importance of shockproof safety extends beyond individual protection; it also encompasses the safety of the entire work environment. Electrical work often takes place in proximity to other workers, equipment, and sensitive installations. A single mistake or equipment failure can have a domino effect, leading to widespread damage and endangering multiple people. By choosing the right lineman gloves, workers can significantly reduce the risk of accidents and create a safer, more secure work environment for everyone involved.

Key Features to Look for in Lineman Gloves

-

Insulation Rating

-

Measured in volts (e.g., Class 00 to Class 4).

-

Indicates the maximum voltage the gloves can safely withstand.

-

Must match the voltage levels encountered in your work environment.

-

-

Material Composition

-

Natural rubber: Offers excellent dielectric properties and flexibility.

-

Synthetic materials (e.g., neoprene): Provide greater durability and resistance to ozone and UV exposure.

-

-

Glove Thickness

-

Thicker gloves offer more protection.

-

However, they may reduce dexterity and fine motor control.

-

-

Ergonomic Design

-

Pre-curved fingers improve fit and ease of movement.

-

Reinforced palms reduce fatigue during extended use.

-

-

Additional Protective Layers

-

Leather over-gloves add abrasion and mechanical protection.

-

Help prolong glove life in rugged conditions.

-

Different Types of High Voltage Lineman Gloves

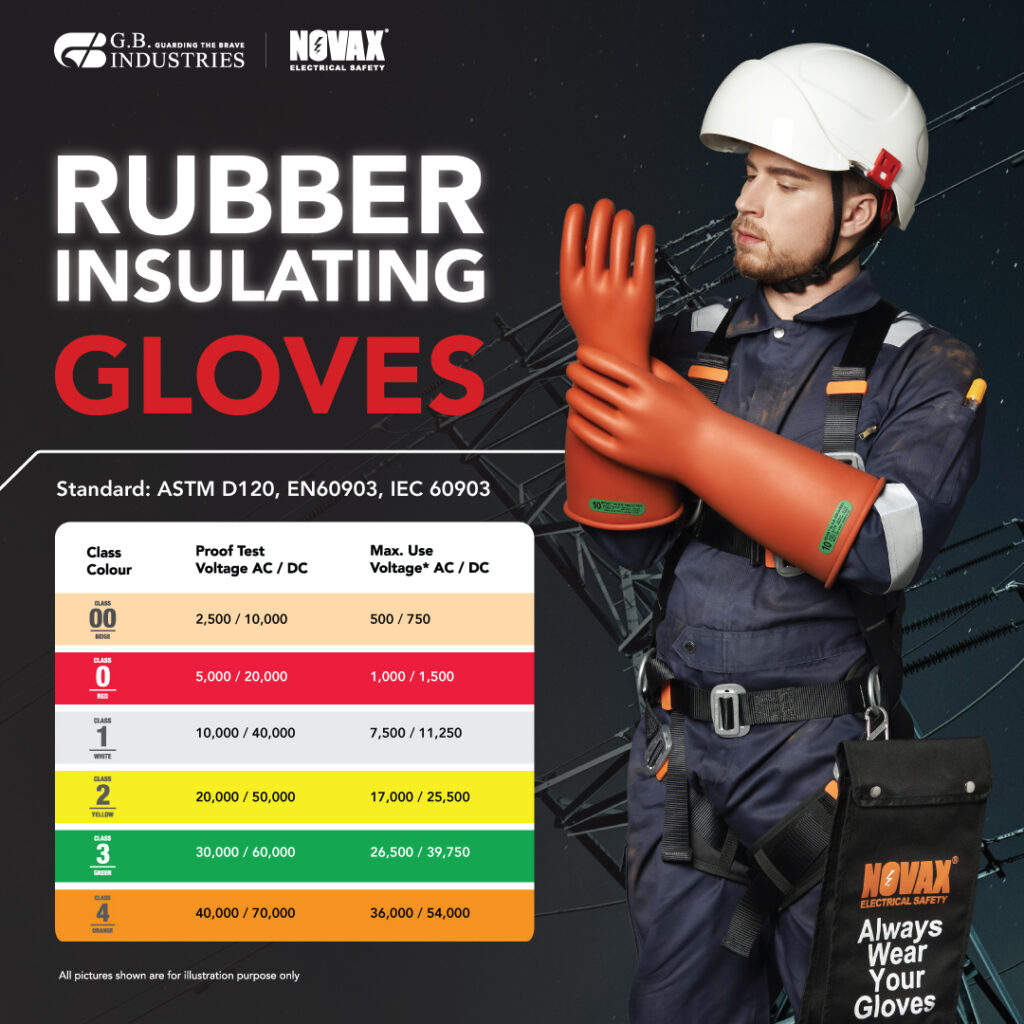

High voltage lineman gloves come in various types, each designed to meet specific needs and requirements. The most common types include Class 00, Class 0, Class 1, Class 2, Class 3, and Class 4 gloves, which are categorized based on their maximum use voltage. Class 00 and Class 0 gloves are suitable for low voltage applications, while Class 1 through Class 4 gloves are designed for higher voltage levels. Understanding these classifications is essential for selecting the right gloves for your particular job.

Class 00 and Class 0 gloves are typically used for low voltage applications up to 500 volts AC and 1,000 volts AC, respectively. These gloves are relatively thin and provide good dexterity, making them ideal for tasks that require precision and fine motor skills. However, they offer limited protection against higher voltage levels and are not suitable for more demanding electrical work.

For higher voltage applications, Class 1 through Class 4 gloves are recommended. Class 1 gloves are rated for use up to 7,500 volts AC, while Class 2 gloves can handle up to 17,000 volts AC. Class 3 and Class 4 gloves provide even higher levels of protection, with maximum use voltages of 26,500 volts AC and 36,000 volts AC, respectively. These gloves are thicker and more robust, offering enhanced protection but potentially reducing dexterity. It is important to choose the appropriate class of gloves based on the specific voltage levels and tasks you will be performing.

Certifications and Standards for Lineman Gloves

Ensuring that your high voltage lineman gloves meet the necessary certifications and standards is crucial for guaranteeing their effectiveness and safety. The primary standard for electrical insulation gloves is ASTM D120, which specifies the requirements for the manufacturing, testing, and performance of rubber insulating gloves. This standard is widely recognized and adhered to by manufacturers to ensure that their gloves provide adequate protection against electrical hazards.

In addition to ASTM D120, other relevant standards include IEC 60903 and EN 60903, which are international standards for live working gloves of insulating material. These standards outline the testing procedures and performance criteria for electrical insulating gloves, ensuring their reliability and safety. Gloves that meet these standards are subjected to rigorous testing, including dielectric testing, mechanical testing, and visual inspection, to ensure their quality and performance.

When purchasing high voltage lineman gloves, it is important to verify that they are certified to the relevant standards and that they have been tested by accredited laboratories. This information is usually indicated on the gloves themselves, along with the manufacturer’s name, glove class, and date of manufacture. By choosing gloves that meet recognized certifications and standards, you can have confidence in their ability to provide the necessary protection for your electrical work.

How to Properly Care for and Maintain Your Gloves

Proper care and maintenance of high voltage lineman gloves are essential to ensure both safety and long-term durability. Follow these best practices to keep your electrical insulating gloves in optimal condition:

✅ 1. Inspect Gloves Before Every Use

-

Visually examine gloves for cuts, punctures, abrasions, or signs of wear.

-

Focus on fingertips, palms, and areas where flexibility is highest.

-

Damaged gloves can compromise insulation protection—always replace if in doubt.

✅ 2. Clean Regularly Using Safe Methods

-

Wash gloves with mild soap and lukewarm water to remove dirt and oils.

-

Avoid solvents, strong chemicals, or rough scrubbing that can degrade rubber insulation.

-

Let gloves air dry naturally—never expose them to heat sources.

✅ 3. Store in Protective Conditions

-

Keep gloves in a cool, dry location, away from sunlight and ozone sources.

-

Use storage bags or containers to prevent deformation and exposure.

-

Avoid folding or compressing gloves, which can weaken the material structure over time.

✅ 4. Follow Testing & Certification Guidelines

-

High voltage gloves must be tested periodically for electrical integrity.

-

Refer to the manufacturer’s schedule based on glove class (00 to 4).

-

Always comply with OSHA and ASTM standards for electrical glove testing.

✅ 5. Use Leather Protectors for Extended Life

-

Pair rubber gloves with leather protectors to guard against physical damage.

-

Never use protectors alone—they’re only effective when used with insulated gloves.

-

Replace protectors when worn or damaged to maintain glove performance.

💡 Tip: Investing in proper glove maintenance not only keeps your team safe but also maximizes ROI by reducing premature replacements.

Top Brands for High Voltage Lineman Gloves

When it comes to high voltage lineman gloves, choosing a reputable brand is essential for ensuring quality and reliability. Several well-established brands are known for their expertise in manufacturing high-quality electrical insulating gloves. NOVAX stand out as industry leaders, offering a wide range of gloves that meet the highest standards of safety and performance.

NOVAX is a brand that specializes in electrical insulating gloves, offering a range of gloves that cater to different voltage levels and applications. NOVAX gloves are made from premium-grade rubber and are designed to provide excellent dielectric properties and mechanical strength. Their gloves are also ergonomically designed to enhance comfort and reduce hand fatigue during prolonged use. With a strong focus on safety and quality, NOVAX has established itself as a trusted brand for high voltage lineman gloves.

Common Mistakes to Avoid When Choosing Gloves

Selecting the right high voltage gloves is vital to ensure personal safety and reliable performance. However, many linemen unknowingly make critical mistakes during the selection process. Here are the top pitfalls to avoid:

❌ 1. Choosing the Wrong Insulation Rating

-

Using gloves with a lower voltage rating than required is a serious safety hazard.

-

Always match the glove’s insulation class (e.g., Class 0, 2, 4) with the voltage level in your work environment.

-

Refer to ASTM D120 and OSHA standards for guidance.

❌ 2. Ignoring Glove Fit and Comfort

-

Ill-fitting gloves can:

-

Reduce dexterity and accuracy

-

Cause hand fatigue or discomfort

-

Slip off or fail to provide a secure grip

-

-

Select gloves in the correct size—many brands offer half sizes or ergonomic designs.

❌ 3. Overlooking Environmental Conditions

-

Temperature extremes, humidity, ozone, and UV exposure can degrade glove performance.

-

Natural rubber gloves may not perform well in high ozone or UV settings.

-

Consider synthetic options (like neoprene) when working in harsh or chemically exposed environments.

❌ 4. Not Verifying Compatibility with Outer Protectors

-

Electrical gloves should always be paired with leather outer protectors to prevent mechanical damage.

-

Choosing the wrong size or style of protector can impact glove integrity and user comfort.

✅ Pro Tip: When in doubt, consult the manufacturer’s specifications and safety guidelines. Proper selection today prevents costly injuries tomorrow.

Real-life Case Studies: The Impact of Quality Gloves

To illustrate the importance of high-quality lineman gloves, let’s consider a few real-life case studies that highlight the impact of choosing the right gloves. In one case, an experienced lineman was working on repairing a high voltage power line during a storm. Despite the challenging conditions, his Class 2 gloves provided the necessary insulation and protection, allowing him to complete the repair safely. The gloves’ ergonomic design also ensured that he could maintain a firm grip on his tools, even in wet conditions.

In another case, a young apprentice was just starting his career in electrical work and was unsure about which gloves to choose. With the guidance of his mentor, he selected a pair of Class 0 gloves that were rated for the voltage levels he would be working with. During a routine maintenance task, he accidentally came into contact with a live wire. Thanks to the high-quality gloves, he was protected from what could have been a life-threatening electrical shock. This experience underscored the importance of using the right PPE and reinforced his commitment to safety.

A third case study involves a seasoned lineman who had been using the same pair of gloves for several years without proper maintenance. One day, while working on a high voltage transmission line, he felt a tingling sensation in his hands, indicating that the gloves were no longer providing adequate insulation. He immediately stopped work and inspected the gloves, finding small cuts and signs of wear that had gone unnoticed. This incident highlighted the importance of regular inspection and maintenance of lineman gloves to ensure their continued effectiveness.

Conclusion: Making an Informed Choice for Safety

In conclusion, choosing the right high voltage lineman gloves is a critical decision that can have a significant impact on your safety and performance in the field. By understanding the importance of shockproof safety, recognizing the key features to look for in lineman gloves, and being aware of the different types and classifications, you can make an informed choice that meets your specific needs. Ensuring that your gloves meet the necessary certifications and standards, and properly caring for and maintaining them, will further enhance their effectiveness and longevity.

Selecting gloves from reputable brands known for their quality and reliability, such as Salisbury by Honeywell, Ansell, and NOVAX, can provide added assurance of protection. Avoiding common mistakes, such as choosing the wrong insulation rating or neglecting proper fit, can help ensure that your gloves provide the necessary protection and dexterity for your work. Real-life case studies underscore the importance of high-quality gloves and the critical role they play in preventing electrical injuries and fatalities.

Ultimately, equipping yourself with the right high voltage lineman gloves is not just about compliance with safety regulations; it is about prioritizing your well-being and that of your colleagues. By making an informed choice and investing in high-quality gloves, you can confidently tackle the challenges of electrical work while minimizing the risks associated with high voltage systems. Stay safe, stay protected, and ensure that your gloves are always your first line of defense against electrical hazards.