Stay Safe and Shock-Free: The Ultimate Guide to Electrical Resistant Gloves

Mon, 30 Jun 2025

Stay Safe and Shock-Free: The Ultimate Guide to Electrical Resistant Gloves

In today’s electrically powered world, electrical resistant gloves are not just a recommendation—they are essential. Whether you’re a professional handling high-voltage equipment or a DIYer fixing a breaker box, choosing the right electrical insulated work gloves is your first step toward complete safety. This comprehensive guide explores everything from rubber insulated gloves for electrical work to the most trusted electrical proof gloves on the market, helping you stay safe, efficient, and shock-free.

Why Electrical Resistant Gloves Matter in High-Risk Jobs

Working with electricity poses serious dangers, from electric shocks to arc flashes and electrical burns. Electrical work gloves act as a barrier, providing the necessary dielectric insulation that prevents current from passing through your body. In industries like utilities, maintenance, and construction, electrical safety is more than a legal requirement—it’s a life-saving necessity.

Companies must prioritize safety by incorporating electrical gloves safety protocols into their operations. This includes using voltage-rated PPE, routine glove testing, and staff training. Beyond preventing injury, proper use of insulated gloves for electrical work reduces liability, increases morale, and boosts productivity.

Moreover, the economic costs of accidents from improper or insufficient protection can be staggering. From legal liability and insurance claims to equipment damage and productivity loss, neglecting proper hand protection is a risk no business can afford. Adopting best practices and certified electrical insulated rubber gloves is not only ethical but also financially prudent.

Types of Electrical Work Gloves You Should Know

Rubber Gloves for Electrical Work: Core Protection

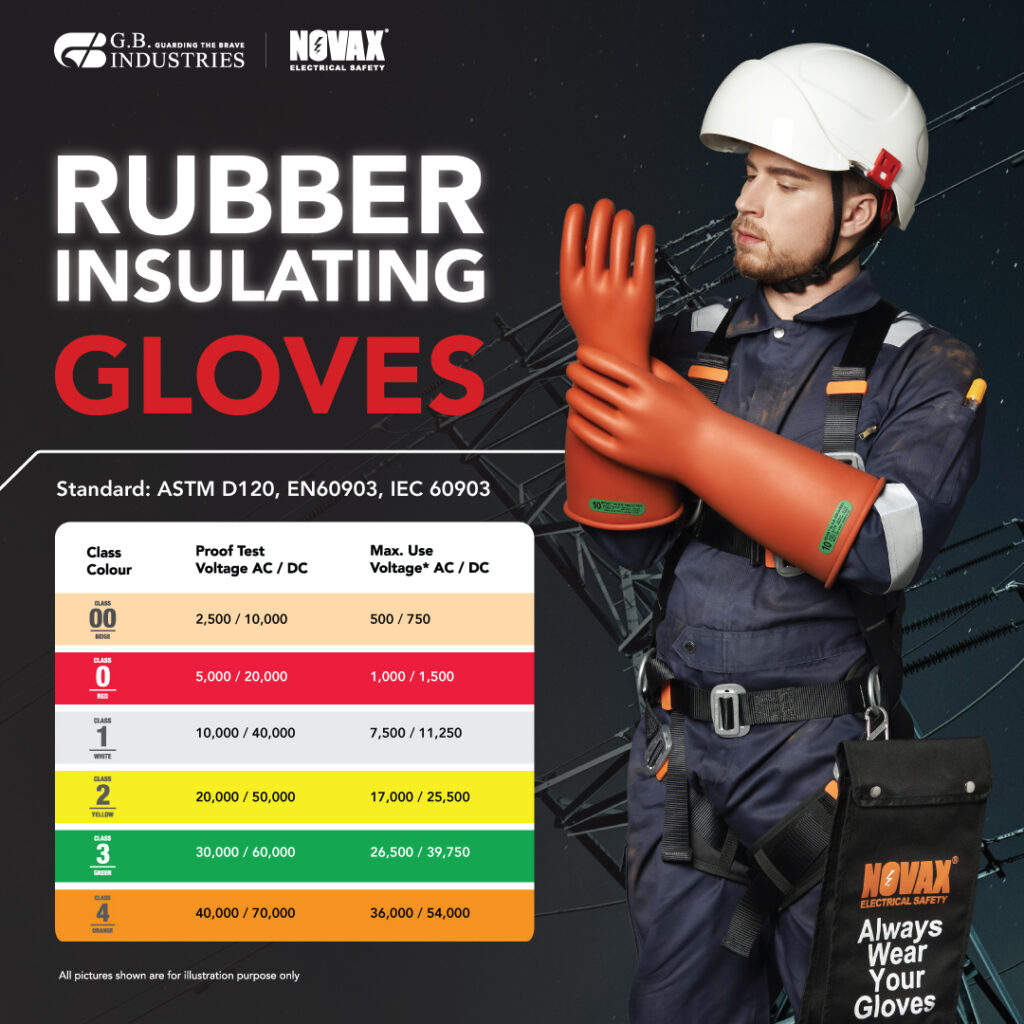

Rubber gloves for electrical work offer unmatched dielectric protection and are categorized by ASTM standards:

- Class 00: Up to 500V

- Class 0: Up to 1,000V

- Class 1: Up to 7,500V

- Class 2: Up to 17,000V

- Class 3: Up to 26,500V

- Class 4: Up to 36,000V

These Electrical Resistant Gloves are a must-have for any work involving energized equipment. Always refer to the color-coding and labeling for each class to avoid confusion in the field.

Leather Protectors: External Shielding

While rubber gloves protect against electricity, they are prone to cuts and abrasions. Leather protective gloves worn over the rubber ones guard against mechanical hazards and improve grip. This dual-layer approach significantly extends the lifespan of the dielectric gloves and reduces replacement frequency.

Understanding Electrical Resistant Gloves & Voltage Ratings

All electrical resistant gloves must meet voltage safety standards set by:

- ASTM D120

- IEC 60903

These standards categorize gloves by voltage capacity and test them for:

- Dielectric strength

- Durability

- Chemical resistance

- Physical performance under stress

The importance of testing cannot be overstated. Dielectric gloves are not immune to degradation. UV exposure, chemical spills, and repeated use weaken the insulation. Therefore, retesting every six months—at a minimum—is a requirement under OSHA guidelines.

Choosing insulated gloves for electrical applications means matching glove class with expected voltage exposure. Never underestimate voltage ratings—using a glove rated below your needs can have fatal consequences.

Choosing the Right Electrical Resistant Gloves

When selecting gloves, consider:

- Voltage Level: Determine the maximum voltage exposure.

- Fit & Comfort: Use manufacturer sizing charts. Too tight or loose affects safety and dexterity.

- Materials: Look for multi-layered options combining rubber, leather, and fabric.

- Usage Duration: Extended wear? Opt for comfort-lined models.

- Environmental Conditions: Heat, moisture, oil, or abrasion can affect glove performance.

Best practice: Pair rubber gloves for electrical work with leather protectors and inspect them before every use. Consider investing in gloves that include RFID chips or barcodes for tracking usage and testing cycles in enterprise settings.

How to Use & Maintain Rubber Gloves for Electrical Work

Daily Inspection Routine

- Visual check: Look for cracks, holes, and cuts.

- Inflation test: Trap air, roll the glove, and listen for leaks.

- Flexibility check: Gently stretch fingers and palm areas.

- Date check: Ensure gloves are within the manufacturer’s shelf-life.

Usage Guidelines

- Only wear gloves within their rated class.

- Don’t expose them to oil, chemicals, or excessive heat.

- Always use leather protectors over rubber gloves.

- Do not use if gloves are damp or improperly stored.

Cleaning & Storage

- Wash with mild soap and lukewarm water.

- Air-dry fully, away from direct heat.

- Store in protective bags or glove boxes in a cool, dark space.

- Avoid compressing or folding gloves.

Well-maintained electrical insulated gloves ensure consistent protection and help your organization pass compliance audits with confidence.

Debunking Myths About Electrical Proof Gloves

Myth 1: All rubber gloves are electrical resistant.

Fact: Only gloves rated under ASTM/IEC / EN standards qualify.

Myth 2: Once bought, gloves don’t need maintenance.

Fact: Regular inspection and retesting are mandatory.

Myth 3: Gloves alone are enough.

Fact: True electrical gloves safety comes from holistic PPE and proper safety procedures.

Myth 4: Higher-rated gloves can replace lower-rated ones in all scenarios.

Fact: Higher-rated gloves may be bulkier, limiting dexterity. Use gloves appropriate to the voltage and task type.

Myth 5: Electrical proof gloves last indefinitely if not used.

Fact: Gloves degrade over time regardless of use. Always check expiration and testing dates.

Key Signs It’s Time to Replace Your Insulated Gloves for Electrical

- Visible damage: Cuts, cracks, or abrasions

- Texture changes: Brittleness or loss of elasticity

- Aging: Over 12 months without retesting

- Label wear: Unreadable voltage or compliance labels

- Failed air test: Leaks detected during inflation test

- Exposure incidents: Contact with chemicals, oils, or arc flash zones

Being proactive ensures you’re not left exposed at a critical moment. Some companies implement digital logs or QR-coded testing schedules to maintain accountability and reduce human error.

Complementing PPE: Beyond Just Electrical Resistant Gloves

Even the best electrical insulated work gloves need backup:

- Insulating sleeves: Extend protection from hand to shoulder

- Dielectric boots: Provide resistance from the ground

- Arc flash hoods: Shield from high-energy events

- Face shields & visors: Protect against blast pressure and debris

- Fire-resistant clothing: Reduces burn risk in arc flash events

Creating a layered safety system with interconnected PPE maximizes protection. Remember, electricity travels in unpredictable paths—don’t leave gaps in your protection.

Final Safety Checklist for Electrical Gloves Safety

- ✅ Use ASTM or IEC or EN rated gloves only

- ✅ Match glove class with voltage level

- ✅ Inspect gloves before each use

- ✅ Test gloves every 6 months (or sooner per use)

- ✅ Wear leather protectors for mechanical protection

- ✅ Pair gloves with dielectric sleeves and boots

- ✅ Keep detailed PPE maintenance logs

- ✅ Train all employees on glove selection and inspection

Frequently Asked Questions (FAQ)

What are electrical resistant gloves used for?

They protect against electric shocks when working on energized circuits.

Are rubber gloves for electrical work safe?

Yes, if certified and rated for voltage exposure and you may wear leather protectors over them to have longer life span.

What’s the difference between electrical proof gloves and insulated gloves?

“Electrical proof” is a non-technical term. Only gloves tested and rated under ASTM/IEC/EN standards qualify as insulated.

How long do electrical work gloves last?

With regular inspections and proper storage, most gloves last 6-12 months depending on usage. Check test and expiry dates.

Can I use one glove type for all electrical tasks?

No. Use glove classes appropriate to voltage and environmental conditions. Higher classes are not always ideal for low-voltage precision work.

Do insulated gloves protect against arc flashes?

They protect against electric current, but arc flash protection requires additional PPE such as face shields and flame-resistant clothing.

Conclusion: Prioritize Electrical Safety with the Right Gloves

High-quality electrical resistant gloves are your front line of defense. From daily jobsite tasks to emergency repairs, they shield you from unseen dangers. Always pair your gloves with the right training, supporting gear, and a rigorous inspection routine.

By choosing the right electrical insulated work gloves, performing regular maintenance, and understanding voltage ratings, you’re making an investment in your safety. Whether you’re dealing with high-voltage repairs or intricate panel work, being equipped with trusted electrical proof gloves ensures confidence and protection.

Safety isn’t optional—it’s operational.

Stay alert. Stay protected. Stay shock-free.