Shockingly Safe: The Ultimate Guide for Electrical Gloves Safety for Maximum Protection

Tue, 1 Jul 2025

Shockingly Safe: The Ultimate Guide for Electrical Gloves Safety for Maximum Protection

When it comes to Electrical Gloves Safety, safety is non-negotiable. The right pair of electrical work gloves isn’t just a protective layer; it’s your first line of defense against electrical hazards. With a myriad of options available, choosing the best gloves can feel overwhelming. Fear not! This ultimate guide will navigate you through the essential qualities to look for, from insulation ratings to comfort and dexterity. Whether you’re a seasoned electrician or a DIY enthusiast, understanding the nuances of electrical work gloves ensures you can work confidently and securely. Join us as we unravel the secrets to selecting gloves that provide shockingly safe protection, empowering you to take on any project with peace of mind. Your safety shouldn’t be an afterthought—it should be the foundation of every electrical endeavor. Let’s dive in and equip you with the knowledge you need to make a smart choice for maximum protection.

Understanding the Importance of Electrical Gloves Safety

When dealing with electrical work, safety is paramount. Electrical work gloves are designed to protect workers from electric shocks, burns, and other hazards associated with electrical currents. These Electrical Gloves Safety provide a necessary barrier between the user and the electrical components, significantly reducing the risk of injury. This is particularly important for electricians, linemen, and other professionals who are frequently exposed to high-voltage environments. By understanding the critical role these gloves play, one can appreciate why selecting the right pair is essential for both personal safety and operational efficiency.

In addition to protection from electrical hazards, electrical work gloves also offer protection against mechanical risks. For instance, gloves can prevent cuts, abrasions, and punctures caused by sharp tools or materials. This dual protection is crucial in ensuring that workers can perform their tasks without fear of injury. Moreover, many electrical work gloves are designed with ergonomic features that enhance grip and dexterity, allowing for more precise and efficient work. This combination of safety and functionality underscores the importance of investing in high-quality electrical work gloves.

Furthermore, regulatory bodies such as the Occupational Safety and Health Administration (OSHA) mandate the use of appropriate personal protective equipment (PPE) in workplaces where electrical hazards are present. Compliance with these regulations not only safeguards workers but also ensures that employers avoid legal repercussions and potential fines. Therefore, understanding the importance of electrical work gloves extends beyond individual safety—it encompasses legal and professional responsibilities as well.

Key Features to Look for in Electrical Gloves Safety

Selecting the right electrical work gloves involves considering several key features that ensure maximum protection and comfort. One of the most critical features is the insulation rating, which indicates the level of voltage protection the gloves provide. Insulation ratings are usually measured in kilovolts (kV), and it’s essential to choose gloves with a rating appropriate for the specific tasks at hand. For instance, a glove rated for 1,000 volts may be suitable for low-voltage tasks, while higher ratings are necessary for more demanding electrical work.

Another important feature to look for is the glove’s material. Different materials offer varying levels of protection and durability. Rubber gloves, for example, are excellent insulators and are commonly used in high-voltage applications. However, they may not provide the same level of mechanical protection as leather or synthetic gloves. Therefore, it’s crucial to assess the specific requirements of the job and select gloves that balance electrical insulation with mechanical resilience.

Comfort and dexterity are also vital considerations when choosing electrical work gloves. Gloves that are too bulky or stiff can impede the wearer’s ability to perform tasks efficiently. Look for gloves that offer a snug fit without compromising flexibility. Features such as reinforced fingertips, breathable materials, and ergonomic designs can significantly enhance comfort and usability. Additionally, some gloves come with inner liners that wick away moisture, keeping hands dry and comfortable during prolonged use.

Types of Electrical Work Gloves: A Comprehensive Overview

Electrical Gloves Safety come in various types, each designed to meet specific safety and operational needs. The primary categories include insulating gloves, leather protector gloves, and arc flash gloves. Understanding the differences between these types is crucial for making an informed choice.

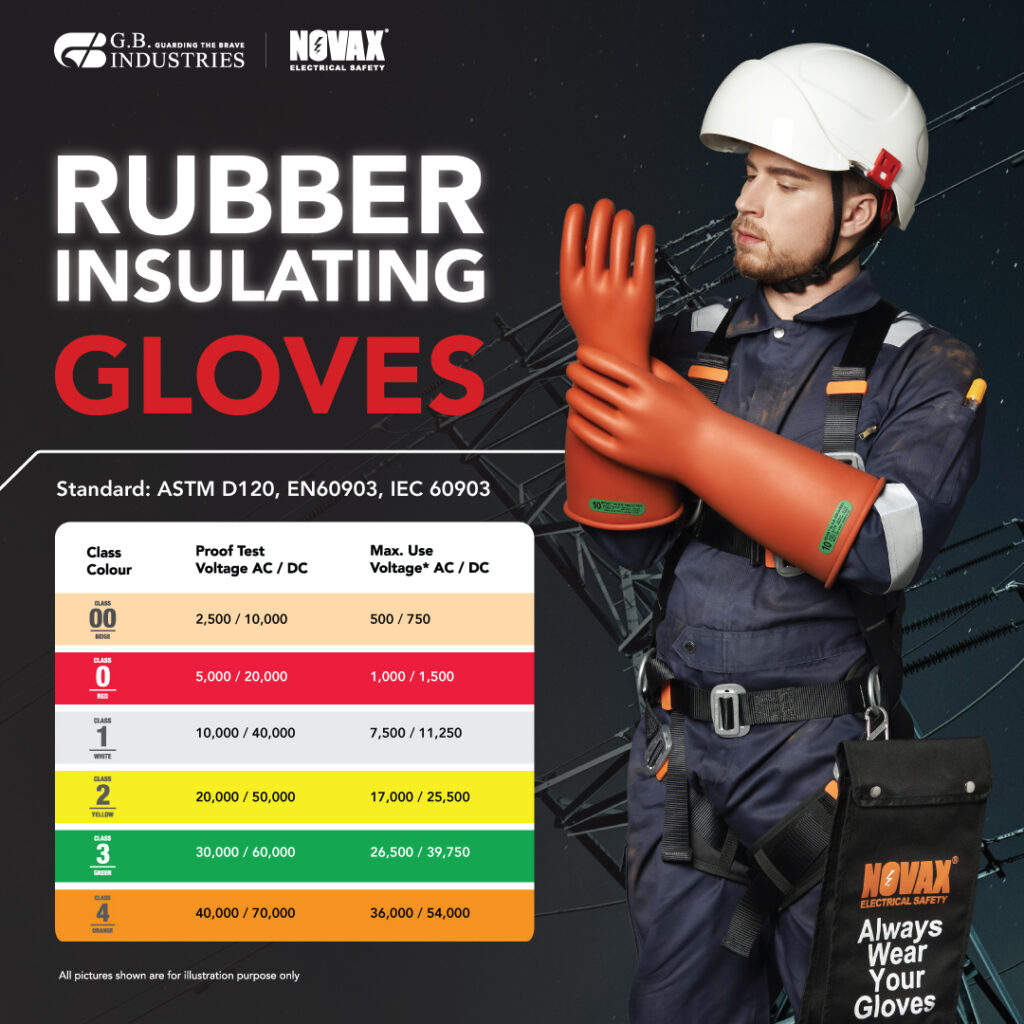

Insulating gloves are made from materials like rubber and are specifically designed to protect against electrical shocks. These gloves are usually color-coded and classified into different classes based on their voltage ratings. For example, Class 0 gloves are rated for up to 1,000 volts AC, while Class 4 gloves can handle up to 36,000 volts AC. It’s essential to select the appropriate class of insulating gloves for the specific voltage levels encountered in your work.

Leather protector gloves are typically worn over insulating gloves to provide additional mechanical protection. While insulating gloves offer excellent electrical resistance, they can be vulnerable to cuts, punctures, and abrasions. Leather protectors help safeguard the insulating gloves from physical damage, thereby extending their lifespan and maintaining their protective qualities. It’s important to ensure that the leather protectors fit properly over the insulating gloves without compromising dexterity.

Arc flash gloves are designed to protect against the intense heat and energy released during an arc flash event. These gloves are made from materials that can withstand high temperatures and minimize the risk of burns. Arc flash gloves are often used in conjunction with other PPE, such as face shields and flame-resistant clothing, to provide comprehensive protection. When selecting arc flash gloves, consider the arc rating, which indicates the level of protection against heat and energy transfer.

Electrical Gloves Safety Guideline

Electrical Gloves Safety ratings are a critical aspect of choosing electrical work gloves. These Electrical Gloves Safety provide a standardized measure of the gloves’ protective capabilities, helping users make informed decisions. One of the primary standards for Electrical Gloves Safety is the American Society for Testing and Materials (ASTM) standards, specifically ASTM D120 for rubber insulating gloves.

The ASTM D120 standard classifies gloves into six classes based on their maximum use voltage. Each class is color-coded for easy identification: Class 00 (beige) for up to 500 volts AC, Class 0 (red) for up to 1,000 volts AC, Class 1 (white) for up to 7,500 volts AC, Class 2 (yellow) for up to 17,000 volts AC, Class 3 (green) for up to 26,500 volts AC, and Class 4 (orange) for up to 36,000 volts AC. It’s essential to select gloves that meet or exceed the voltage requirements of the tasks you’ll be performing.

In addition to voltage ratings, users should consider the gloves’ mechanical protection ratings. These ratings indicate the gloves’ resistance to punctures, cuts, and abrasions. For instance, the ANSI/ISEA 105 standard provides a rating system for cut resistance, ranging from A1 (minimal cut resistance) to A9 (maximum cut resistance). Understanding these ratings can help users select gloves that provide both electrical and mechanical protection.

Another important safety rating to consider is the arc flash rating, measured in calories per square centimeter (cal/cm²). This rating indicates the level of protection provided against the thermal energy of an arc flash. The higher the arc rating, the greater the protection. When selecting gloves for tasks that involve potential arc flash hazards, it’s crucial to choose gloves with an appropriate arc rating to ensure maximum safety.

-

OSHA Standard 1910.137 – Electrical Protective Equipment

Covers test intervals, voltage classes (00 to 4), and retest rules for insulating gloves

https://www.osha.gov/laws-regs/regulations/standardnumber/ -

OSHA eTool – Insulating Gloves and Sleeves

Details testing, inspection, proper use of leather protectors, and best-practice care guidelines

https://www.osha.gov/etools/electric-power/general/personal-protective-equipment/ -

Grainger KnowHow – Electrical Gloves: Inspection and Classification

Practical advice on visual inspection, air testing, and equipment classification

https://www.osha.gov/etools/electric-power/general/personal-protective-equipment/ -

Electrical Safety Pub – Best Practices for Electrical-Gloves Safety Programs

Explains combined use of insulating gloves and leather protectors, including cuff overlap standards

https://www.electricalsafetypub.com/features/electrical-gloves-best-practices-for-building-an-electrical-safety-program/ -

Journal of Burlington Safety – Electrical Safety Gloves 101

Covers ASTM D120 voltage classes, glove types, and accessory recommendations

https://www.burlingtonsafety.com/blog/electrical-safety-gloves-101/

The Role of Material in Electrical Gloves Safety

The material of Electrical Gloves Safety plays a significant role in determining their protective qualities and overall performance. Different materials offer varying levels of electrical insulation, mechanical protection, and comfort. Therefore, understanding the properties of these materials is essential for selecting the right gloves for specific tasks.

Rubber is one of the most common materials used in electrical insulating gloves. Rubber gloves provide excellent electrical resistance, making them ideal for high-voltage applications. They are flexible and can conform to the shape of the hand, ensuring a secure fit. However, rubber gloves can be susceptible to cuts and abrasions, which is why they are often paired with leather protector gloves. Regular inspection and proper maintenance are crucial to ensure the integrity of rubber gloves.

Leather is another widely used material in electrical work gloves, particularly in protector gloves. Leather gloves offer superior mechanical protection, shielding the hands from cuts, punctures, and abrasions. They are durable and provide a good grip, making them suitable for handling tools and materials. However, leather does not provide electrical insulation, so it should always be worn over insulating gloves.

Synthetic materials, such as Kevlar and neoprene, are also used in electrical work gloves. Kevlar offers excellent cut resistance and is often used in gloves designed for tasks that involve sharp objects. Neoprene provides good chemical resistance and can be used in gloves that need to withstand exposure to oils, solvents, and other chemicals. These synthetic materials can be combined with rubber or leather to create multi-functional gloves that offer both electrical and mechanical protection.

Top Brands for Electrical Gloves Safety: Why NOVAX® Stands Out

When it comes to Electrical Gloves Safety, several well-known brands offer reliable protection. However, among the top names in the industry, NOVAX® has emerged as a leading brand dedicated exclusively to electrical safety, offering unmatched quality and value. Here’s a comparison of the top contenders — and why NOVAX® is often the preferred choice for professionals.

NOVAX® – Unmatched Smoothness and Dexterity in Electrical Gloves

NOVAX® rubber insulated gloves are engineered specifically for electrical insulation, but what truly sets them apart is their remarkably smooth inner finish and ergonomic flexibility. This results in greater dexterity, reduced hand fatigue, and better grip control, even during precision tasks.

Why professionals prefer NOVAX®:

-

Soft and smooth inner lining for enhanced wearing comfort

-

Designed to minimize hand strain during extended use

-

Superior flexibility allows fine finger movements without sacrificing safety

-

Available from Class 00 to Class 4, all individually tested to ASTM D120 & IEC 60903 & EN60903 standards

-

Maintains high elasticity without feeling bulky or rigid

-

Perfect match with NOVAX® leather protectors for full hand safety

Whether you’re working on energized lines or performing delicate repairs, NOVAX® gloves give you the confidence of high-voltage protection with the comfort of a second skin.

Maintenance Tips for Prolonging the Life of Your Electrical Gloves

Proper maintenance is essential for ensuring the longevity and effectiveness of electrical work gloves. Regular inspection, cleaning, and storage practices can help maintain the gloves’ protective qualities and extend their lifespan. Here are some key maintenance tips to follow.

First, inspect your gloves before each use. Look for signs of wear and tear, such as cuts, punctures, and abrasions. Check for any degradation in the material, especially in rubber gloves, as even small defects can compromise their electrical insulation. If you notice any damage, replace the gloves immediately to avoid potential hazards. Regular inspection is crucial for identifying issues early and ensuring that your gloves provide the necessary protection.

Cleaning your gloves regularly is also important for maintaining their performance. For rubber insulating gloves, use a mild soap and water solution to remove dirt and contaminants. Avoid using harsh chemicals or solvents, as they can degrade the rubber material. After cleaning, dry the gloves thoroughly before storing them. Leather protector gloves can be cleaned with a damp cloth and a leather cleaner if needed. Keeping your gloves clean helps prevent the buildup of harmful substances that could compromise their integrity.

Proper storage is another key aspect of glove maintenance. Store your gloves in a cool, dry place away from direct sunlight and heat sources. Use a storage bag or container to protect them from dust and debris. Avoid folding or creasing rubber gloves, as this can cause cracks and weaken the material. By following these storage practices, you can help preserve the gloves’ protective qualities and extend their usable life.

Common Mistakes to Avoid When Choosing Electrical Work Gloves

Choosing the right electrical work gloves is crucial for safety, but there are common mistakes that users should avoid to ensure they make an informed decision. One common mistake is selecting gloves based solely on price. While cost is an important factor, it should not be the only consideration. Cheap gloves may not provide the necessary protection or durability, leading to increased risk and more frequent replacements. Investing in high-quality gloves from reputable brands is a smarter choice for long-term safety and performance.

Another mistake is overlooking the importance of proper fit. Gloves that are too loose or too tight can compromise both safety and comfort. Loose gloves may slip off or reduce dexterity, while tight gloves can restrict movement and cause discomfort. It’s essential to choose gloves that fit snugly without being restrictive. Many brands offer sizing charts and guides to help users select the right size, so take the time to measure your hands and choose accordingly.

Neglecting to consider the specific requirements of the job is another common mistake. Different tasks may require different levels of protection and features. For example, high-voltage work requires gloves with higher insulation ratings, while tasks involving sharp tools may need gloves with enhanced cut resistance. Assess the specific hazards and demands of your work and choose gloves that provide the appropriate protection and functionality.

Real-Life Case Studies: The Impact of Proper Glove Selection

Real-life case studies highlight the critical importance of selecting the right electrical work gloves. These examples demonstrate how proper glove selection can prevent injuries and save lives, underscoring the need for careful consideration and adherence to safety standards.

In one case, a utility worker was performing maintenance on a high-voltage power line when an unexpected surge occurred. Thanks to his Class 2 rubber insulating gloves, he was protected from the potentially lethal shock. The gloves’ high insulation rating and proper fit provided a crucial barrier, allowing the worker to escape unharmed. This incident illustrates the importance of choosing gloves with the appropriate voltage rating for the specific task.

A second case study highlights the significance of proper glove maintenance. A lineman regularly inspected and cleaned his rubber insulating gloves, ensuring they were in good condition. During a routine inspection, he discovered a small puncture in one glove and replaced it immediately. Shortly after, he encountered a live wire while working on a power pole. The new gloves provided the necessary insulation, preventing a potentially fatal shock. This example shows how regular inspection and maintenance can play a crucial role in safety.

Conclusion: Making an Informed Choice for Safety and Comfort

Selecting the best electrical work gloves is a critical step in ensuring safety and efficiency when working with electrical systems. By understanding the importance of these Electrical Gloves Safety, recognizing key features, and choosing the appropriate type for specific tasks, users can significantly reduce the risk of electrical hazards. Assessing safety ratings, considering the role of material, and comparing top brands further enhance the decision-making process.

Proper maintenance practices, such as regular inspection, cleaning, and storage, are essential for prolonging the life of electrical work gloves and maintaining their protective qualities. Avoiding common mistakes, such as choosing gloves based solely on price or overlooking the importance of fit, can help users make informed choices that prioritize safety and comfort. Real-life case studies underscore the critical impact of proper glove selection and maintenance, highlighting the need for careful consideration and adherence to safety standards.

Ultimately, the right pair of electrical work gloves is more than just a protective layer—it’s a vital component of a comprehensive safety strategy. By equipping themselves with the knowledge and tools to select the best gloves, users can work confidently and securely, knowing they are well-protected against electrical hazards. Your safety should always be the foundation of every electrical endeavor, and choosing the right Electrical Gloves Safety is a key part of building that foundation. Make an informed choice and prioritize your safety and comfort in every task.