The Ultimate Guide to Gloves for Electrical Work: Types, Insulation & Safety

Fri, 6 Jun 2025

Discover everything you need to know about gloves for electrical work. Learn the best types, insulation materials, safety standards, and sizing tips to protect yourself on the job.

Introduction

When working around electrical hazards, the right gloves are not optional—they’re life-saving. Whether you’re an electrician, engineer, or industrial worker, knowing what gloves to use for electrical work is essential. In this ultimate guide, we’ll break down the types, materials, standards, and safety practices you need to follow to ensure maximum protection.

At NOVAX®, we don’t just manufacture gloves, we help power your safety with globally certified electrical protection gear trusted by professionals in over 40 countries.

Why Gloves for Electrical Work Matter

Electric shock, arc flashes, and burns are just a few of the hazards that come with electrical tasks. The right pair of insulating gloves protects you by forming a non-conductive barrier between your hands and live circuits.

“You can replace tools, but you can’t replace your life.”

Did You Know? According to OSHA 1910.137, insulating gloves must meet rigorous safety and testing standards before use. Our gloves not only comply with OSHA but comply with ASTM and IEC standards too.

Types of Electrical Gloves

There are generally three types of gloves used for electrical protection:

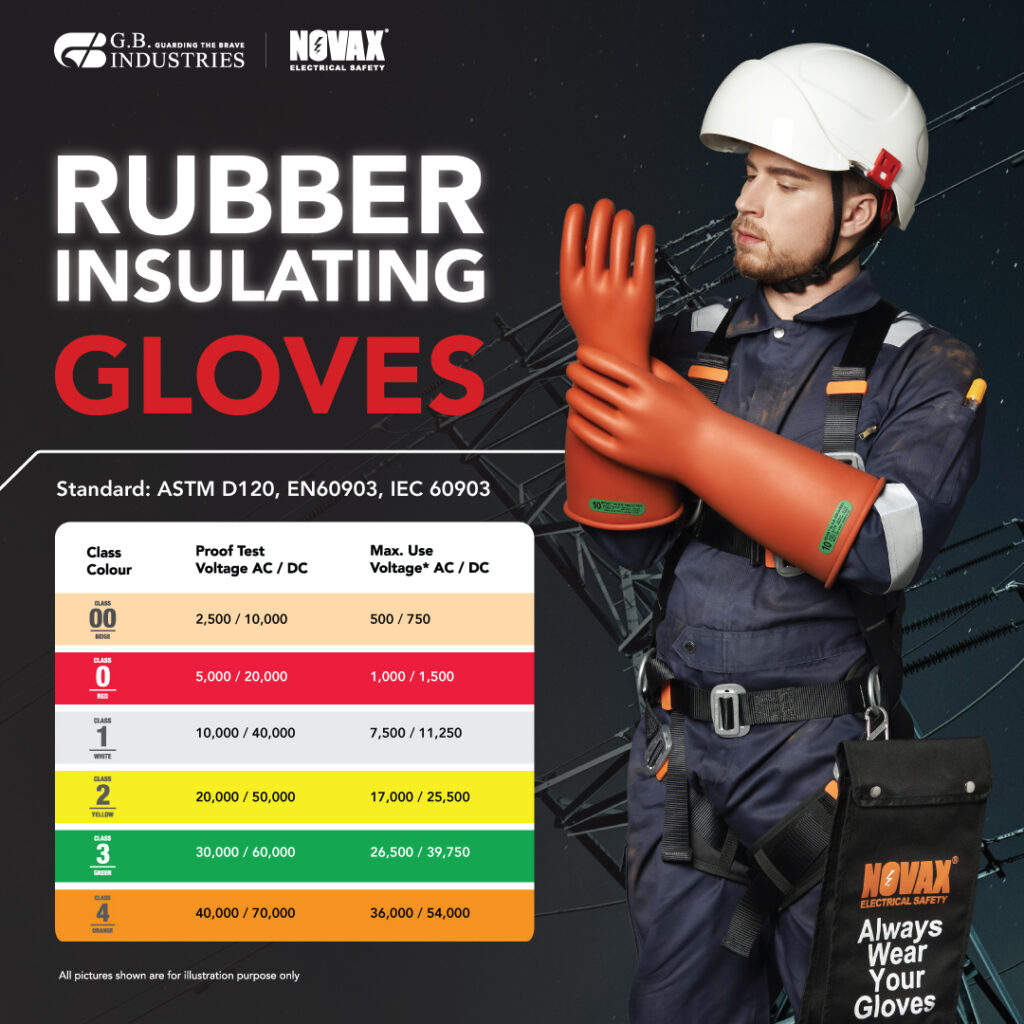

- Rubber Insulating Gloves

- Primary protection against electrical shock

- Must meet ASTM D120 and IEC 60903 standards

- Available in Classes 00 to 4

- Explore our Rubber Insulating Gloves collection.

- Leather Protectors

- Worn over rubber gloves to prevent mechanical damage

- View our Leather Protector Gloves for enhanced safety

- Complete Glove Kits

- Includes insulating gloves, leather protectors, and storage bags

- Perfect for field-ready electricians and utility teams

👉 Not sure which glove class you need? Check out our Electrical Glove Class Guide.

Best Materials for Insulation

NOVAX® gloves are made using an eco-friendly aqueous dipping process, resulting in:

- High dielectric strength

- Enhanced flexibility

- Comfortable fit for long hours

- Natural Latex Rubber: Ideal for flexibility and shock protection

🔗 Learn more on our Insulating Gloves product page.

Safety Standards to Know

We rigorously test our gloves to meet global safety standards:

- ASTM D120 – U.S. benchmark for insulating rubber gloves

- IEC 60903 – International standard for electrical safety gloves

- EN 60903 – European compliance certification

- ISO 9001 – Manufacturing and environmental management systems

Choosing the Right Glove for the Job

Matching the glove to the voltage and environment is crucial:

- Class 00 & 0: Ideal for residential and low-voltage work

- Class 1 & 2: Suitable for commercial and industrial setups

- Class 3 & 4: Required for high-voltage utility and substation work

Don’t forget to assess environmental conditions like temperature, moisture, and presence of oils or chemicals that could compromise glove integrity.

Sizing and Comfort

- ASTM D120 – Sizes 8 – 12 (Half sizes are available upon request)

- EN 60903 – Sizes 8 – 12 (No half sizes available)

Which Glove Size Is Right For Me?

NOVAX® recommends the ‘Palm Measurement’ where you measure the circumference around the palm to determine the size of the glove. This would equate to the probable size of glove to select. Personal preference for tightness and finger length will ultimately determine the glove size that is deemed most comfortable. Allow for addition room if glove liners to be worn.

| Sizes | 8 | 8 ½ | 9 | 9 ½ | 10 | 10 ½ | 11 | 11 ½ | 12 |

| Palm Circumference Measurement | 203mm (8″) | 216mm (8 ½”) | 229mm (9″) | 241mm (9 ½”) | 254mm (10″) | 267mm(10 ½”) | 279mm (11″) | 292mm(11 ½”) | 305mm (12″) |

Tips for perfect fit:

- Measure your hand circumference above the knuckles

- Consider glove thickness with and without protectors

- Ensure no excessive finger slack or tightness

Your gloves should feel like a second skin, snug, but never restrictive.

Maintenance and Inspection

Proper glove care is essential to ensure continued protection. Follow these steps:

- Daily inspection: Look for cuts, holes, or swelling before each use.

- Inflation test: Inflate gloves slightly and check for air leaks.

- Routine Cleaning: Clean electrical rubber gloves using mild soap and lukewarm water.

- Storage: Keep in a cool, dry place away from direct sunlight, heat sources, and ozone.

We also recommend retesting every 6 months as per OSHA guidelines.

Common Questions

What gloves do electricians use?

Class 0 or Class 00 electrical rubber insulating gloves with leather protectors are most common among electricians.

Are leather gloves safe for electrical work?

Only when used over electrical insulating rubber gloves. Leather alone offers no electrical protection.

How often should gloves be tested?

Every 6 months, and before each use.

Do glove materials affect dexterity?

Yes. Our aqueous-dipped gloves provide improved dexterity without sacrificing protection.

Can gloves resist both electrical and mechanical hazards?

Yes, when used as a complete system: rubber insulating gloves plus leather protectors.

Final Thoughts

Electrical safety starts at your fingertips. At NOVAX®, we’re committed to providing high-performance insulating gloves trusted by utility professionals, electricians, and energy workers worldwide.

🛒 Ready to upgrade your gear? Shop Gloves for Electrical Work or talk to us for custom orders.

For ongoing tips, industry updates, and safety resources, visit our Blog.

NOVAX® Guarding The Brave